Quality controls are integral to the John-Valve production process and checks are carried out throughout manufacturing process

Quality controls are integral to the John-Valve production process and checks are carried out throughout manufacturing process. Each casting procedure is inspected and strictly follows PED and International standards. In addition, each casting is required to undergo a series of tests ( destructive or non-destructive, such as PMI, VT, PT, RT, etc.) to ensure our high quality.

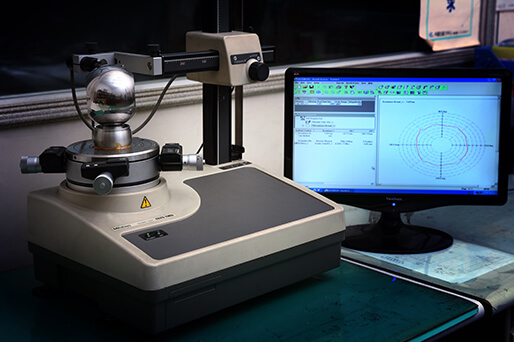

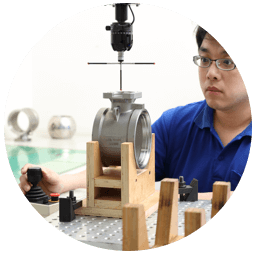

3D Coordinate Measuring Machine

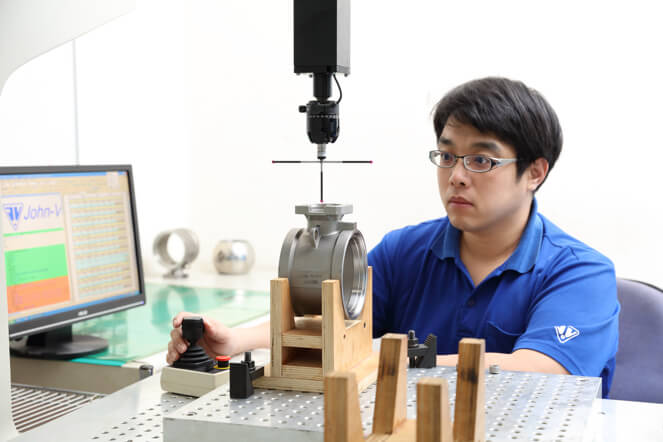

Universal Testing Machine

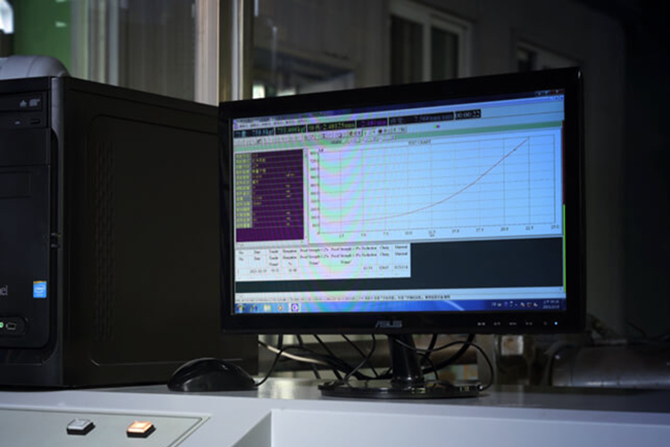

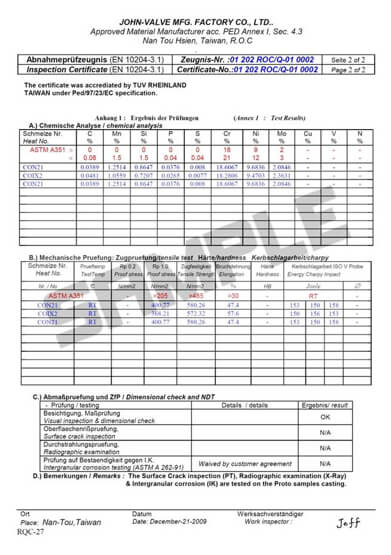

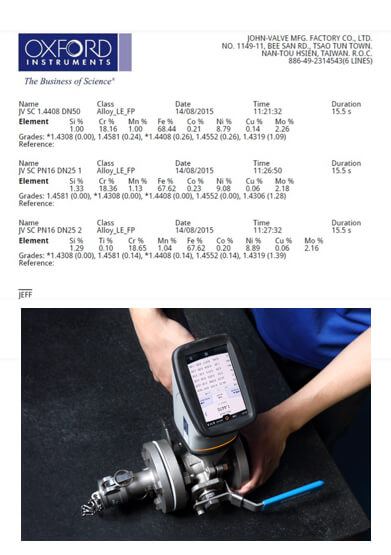

Analysis of the molten alloy's chemical composition using a Spark Spectrometer. After casting and the subsequent Heat Treatment, further testing is conducted using Metallurgical Micro-Structural Analysis. Every casting piece is checked with heat number control and traceability. Additional tests of the Tensile and Charpy impact test, Strength, and the material's hardness by using a Universal Test Machine. For Cryogenic service, we can perform the Charpy test at -196 Celsius degrees. Smoothness test on our machining surface. The additional X-Ray and Dye-penetration tests are available upon the customer's request. Constant visual inspection by the trained inspector helps to maintain very high-quality standards. Torque control on all valves. We also use the 3D Coordinate Measure Machines to control the accuracy of our product's dimensions.

According to EN 12266-1 & API 598 request, 100% of the Air & Hydrostatic pressure testing is conducted before shipment. We issue the correspondent material certificate and test reports for each of our valves.

Exclusive Quality Assurance Procedures

John-Valve’s Low Temperature Charppy Test at Minus degree Celsius in house laboratory (reach to -196˚C )

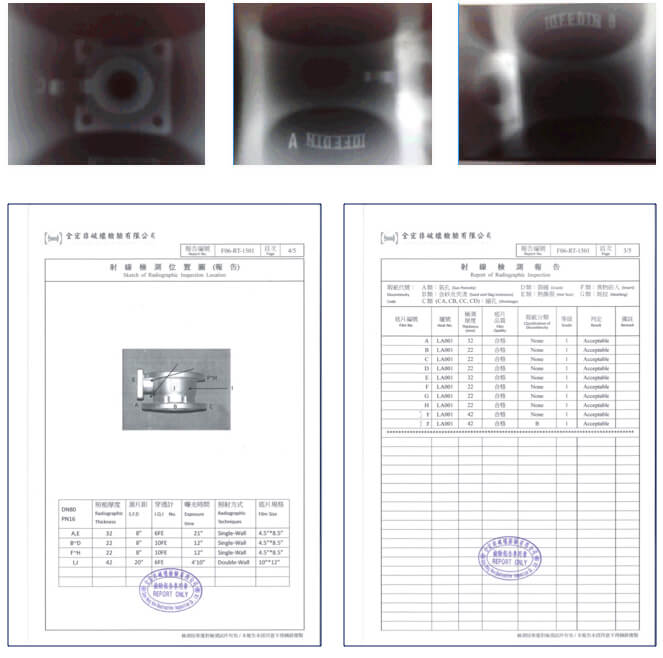

Radiographic Test ( X-Ray ) take from different angles of John-Valve’s Casting piece to ensure quality

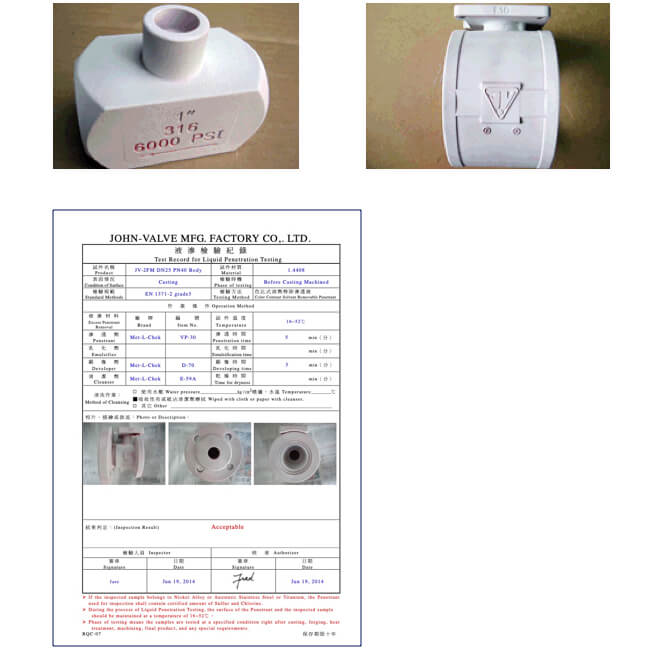

John-Valve’s Certified Surveyor’s Dye

Penetration Test

Quality controls are integral to the John-Valve production process and checks are carried out throughout manufacturing

Our operational quality assurance system aims to provide autonomous quality control through proactive prevention, detection, and correction. And documentation throughout the entire value-added production process.

Every team leader and employee has completed and been certified with the ISO-9001 Quality Assurance Program. In addition, training sessions are held regularly to ensure that the best practices and the highest standards are maintained.

In-plant Testing Laboratory Capability :

- 3D coordinate measuring machine

- Air & Hydrostatic test

- Large size valve pressure test up to 48."

- Chemical Analysis

- PMI test

- Tensile & Charpy impact test

- Cryogenic test

- Life cycle test

- NDT- Dye penetration testing and X-Ray testing

- HVOF Metal Ball & Seats Lapping & Testing

Quality Control Traceability:

- Works Certificate/ Mill certificate (EN 10204/3.1) is provided for all of our products

- 100 % Pressure test quality control before shipment.

- 100% Torque control for all our valves

- Heat Treatment process

- All parts are marked with Heat Numbers for traceability and quality control.

- Technical Support for our products

- Fast Replacement of worn parts

- Long term support: We offer up to 10 years of spare parts availability

All these tests and measuring equipment are regularly calibrated and monitored by an independent 3rd party test laboratory.

Standard Quality Assurance Procedure

Chemical Analysis

( Spark Spectrometer )

Parts FromSame Furnace are

Marked with Same Heat Numbers

Microstucture

Examination

Charpy Impact Test

Tensile Test

Examining

Components

Hydrostatic Testing

Air Testing

Tensile Testing

Destructive Testing

Brinell Hardness Test / Charpy Impact Test

X-Ray Testing - RT

Non Destructive Testing

Dye Penetration Test-PT

VIDEO SHOWCASE

VIDEO SHOWCASE